Fabricators are critical in the formation of the physical world we live in. Sculptures Fabrication By turning raw materials into useful products. Fabrication is the art and science of producing the scaffolding of gigantic metal structures and bridges, delicate machine components, or works of art inspired by metals. This is a very professional occupation that demands technical knowledge, innovation, understanding of materials and the production methods.

Are you looking to choose a career in fabrication, run a company that uses metal fabrication, or just looking to know how normal structures are created? This blog will take you through it all in terms of the fabrication world.

What Is a Fabricator?

A fabricator is a skilled workman who assembles products or parts by cutting, forming, attaching and joining materials, usually metal, but plastic or composite materials can also be used. It will entail the type of converting the raw stock material (sheets, rods, and bars) into finished products in manufacturing, construction, the automotive industry, aerospace, and numerous others.

Fabricators usually have elaborate blueprints, engineering drawings or computer-aided design (CAD) files. They aim at getting these designs to life and in a precise and functional manner.

To keep it simple, a fabricator constructs what has been designed by an engineer.

Types of Fabricators

Fabrication is a very wide area that covers multiple specialisations, which have different tools and expertise. There are some large categories of fabricators of:

Metal Fabricators:

These specialists deal with steel, aluminium, and copper metals to create structures such as the frames, panels, and inclosures. They find application in such industries as shipbuilding, automotive and heavy machinery.

Structural Fabricators:

Structural fabricators specialise in the manufacturing of parts of large building projects, such as bridges, buildings, towers, and structures. They deal with heavy materials and are required to observe strict safety and engineering requirements.

Sheet Metal Fabricators:

These fabricators specialise in producing HVAC ducts, kitchen equipment and inclosures made of thin metal sheets. In this sector, accuracy in cutting and shaping is important.

Plastic Fabricators:

The professionals shape, cut and bond plastic materials to produce the parts that are applied in medical devices, electronics and consumer products.

Custom Fabricators:

Custom fabrication Custom fabrication Custom fabrication Custom fabrication requires designing and making unique components or artistic installations depending on the needs of a particular client, which can often combine creativity and technical expertise.

Major duties of a fabricator.

Some of the typical responsibilities of a fabricator in the industry are varied depending on the industry they are working in; however, some of their duties include:

- Reading and interpretation of blueprints and technical drawings.

- The choice of good materials to be used in the project.

- Laying and labelling materials prior to cutting.

- Having equipment and tools such as saws, grinders, plasma cutters and welding agents.

- Putting together parts through welding, riveting or bolting.

- Checking of finished products to ascertain quality standards.

- Keeping equipment and tools efficient and safe.

- Working with the engineers, welders, and technicians to achieve project objectives.

This is due to the fact that attention to detail is a crucial aspect since even minute errors in measurement would impact the performance or safety of the end product.

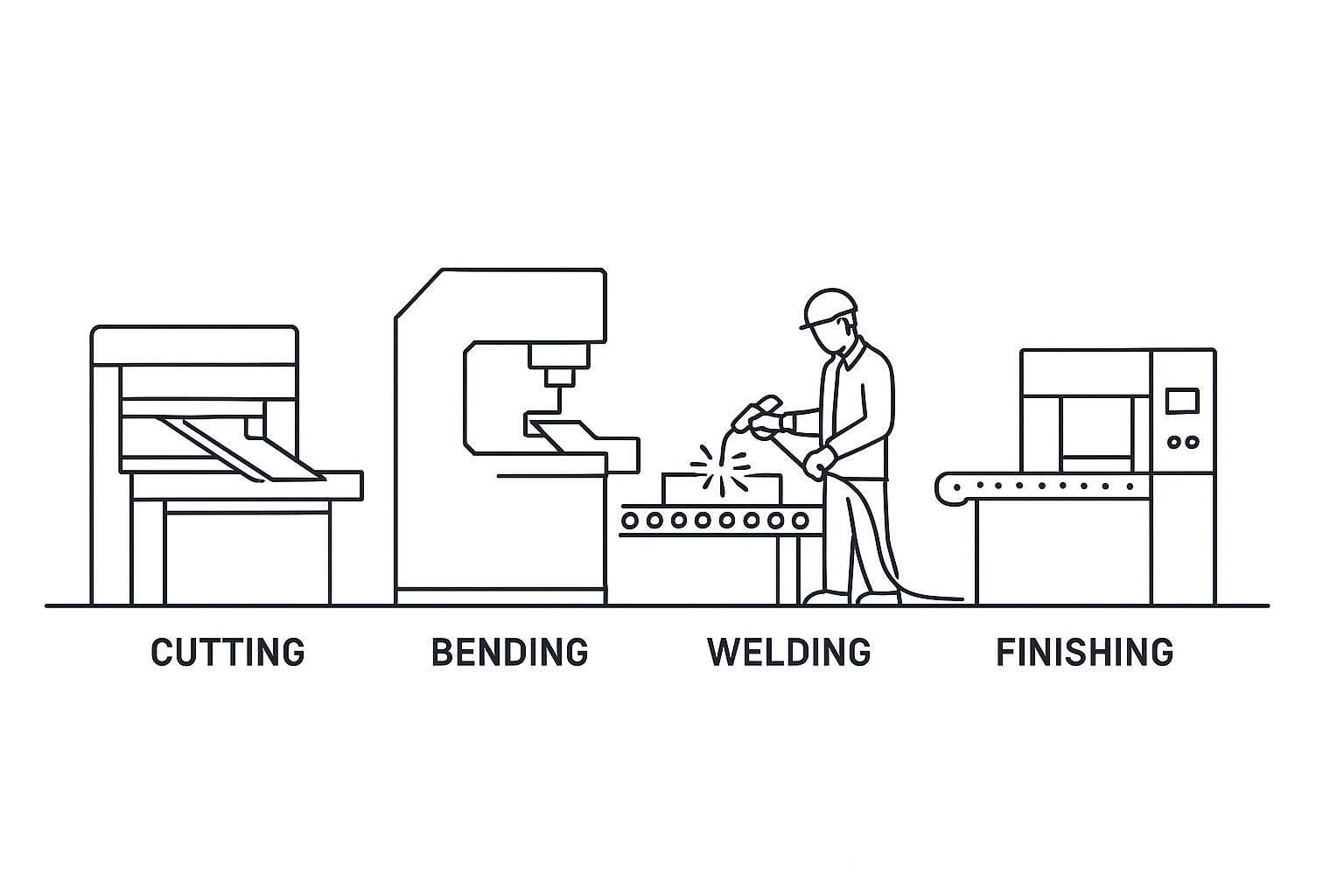

The Fabrication Process

The process of fabrication is a gradual process that transforms the ideas in design into the physical products. Although particular procedures differ with each project, the overall process is as follows:

Design & Planning:

Plans are developed by engineers or designers that include dimensions, materials and tolerances. Fabricators go through these designs in order to know the extent of work.

Material Selection:

It depends on the necessary project, as the right material is selected according to the project needs; it may be strength, weight, corrosion resistance, or heat tolerance.

Cutting:

Laser cutters, water jets, plasma torches or mechanical saws are used to cut materials to the accurate sizes.

Forming & Shaping:

Machines such as press brakes or rollers are used to bend, roll or press the cut materials to the required shapes.

Assembly:

The shaped parts are installed and assembled through welding, bolting or riveting.

Finishing:

Surfaces can be ground or polished after assembly or finished to enhance the look and life. Familiar finishes are painting, powder coating or galvanising.

Inspection & Quality Control:

Each product is carefully inspected to make sure it is of specifications and safe standards.

This combination of the hand, the machine, and technical knowledge covers fabrication as a craft, both technical and artistic.

The Talents to Become a Fabricator

The ability to fabricate requires a combination of technical, physical and problem-solving skills. These are the most significant ones:

Technical competence: Knowledge of blueprints and technical drawings.

Mathematical accuracy: The quantification and computation of dimensions.

Mechanical ability: Knowledge of tools, machines and value maintenance.

Knowledge in welding and cutting: On the various types of welding and safety requirements.

Fine details: Minor mistakes can result in rework or failure of the product.

Teamwork and communication: Collaboration with engineers, welders and supervisors.

Physical strength: Fabrication can be associated with lifting heavy materials and long hours of standing.

With the use of automation and robotics becoming increasingly popular in the manufacturing industry, knowledge of CNC (Computer Numerical Control) machines and robotics welding systems is becoming more useful.

Opportunities in the field of fabrication

Fabrication provides a variety of opportunities and rewarding careers in most fields. Career paths: Some of the typical ways to go would be:

- Metal Fabricator

- Structural Steel Worker

- Welder-Fabricator

- Sheet Metal Worker

- Pipefitter

- CNC Operator

- Production Supervisor

The skilled fabricators can be transferred into the position of supervisor, designer, or quality controller – or even open their own fabrication company. As the world needs construction, infrastructure and manufacturing, the skilled fabricators are always in demand.

The metal fabrication market is expected to keep on increasing in line with the global industry reports, which show that urbanisation, renewable energy, and industrialisation have propelled the metal fabrication market.

Challenges in Fabrication

In spite of its relevance, fabrication is associated with difficulties. These include:

- Being accurate when dealing with narrow deadlines.

- Providing safety of workers in hazardous conditions.

- The adoption of automation and electronic aids.

- Controlling material expenses and supply chain problems.

- Educating the future generation of skilled workers.

Conclusion

The job of a fabricator does not end at cutting and welding metal but includes making the world we live in a world of bridges, machine power, and products to make everyday life possible.

Fabricators are always ahead of the game as industries advance, and they are using a mix of craft, innovation, and accuracy of engineering in order to shape the future. Whether you are working as a fabricator or otherwise, knowing this craft makes you be thankful for the talent and effort which is invested in every completed object.